-

Multi-Lane Inspection Solution with Checkweigher and X-ray Inspection System

Space-saving and cost-effective combined solution with Multi-Lane Checkweigher and X-ray Inspection System improves the production efficiency.

2:38

-

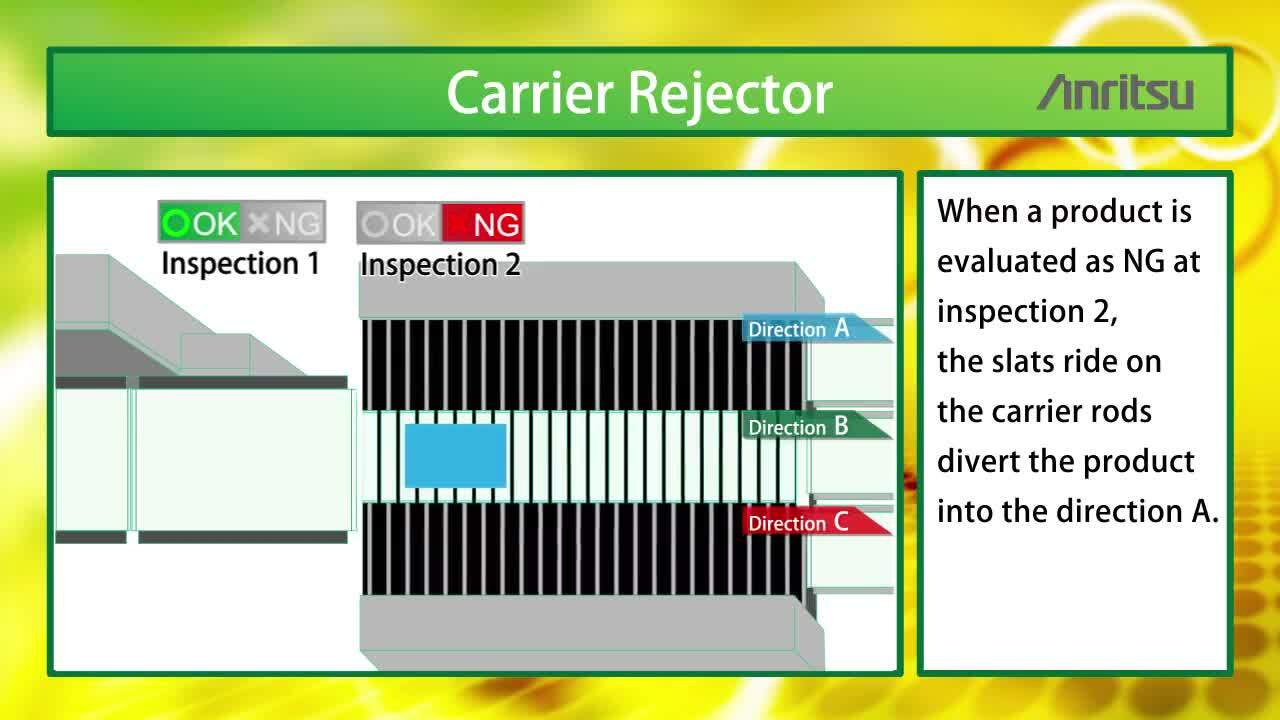

Carrier Type

NG products are sorted horizontally without any shock due to rejection. Since the rejection process doesn't cause any damage, it is ideal for fragile products.

0:59

-

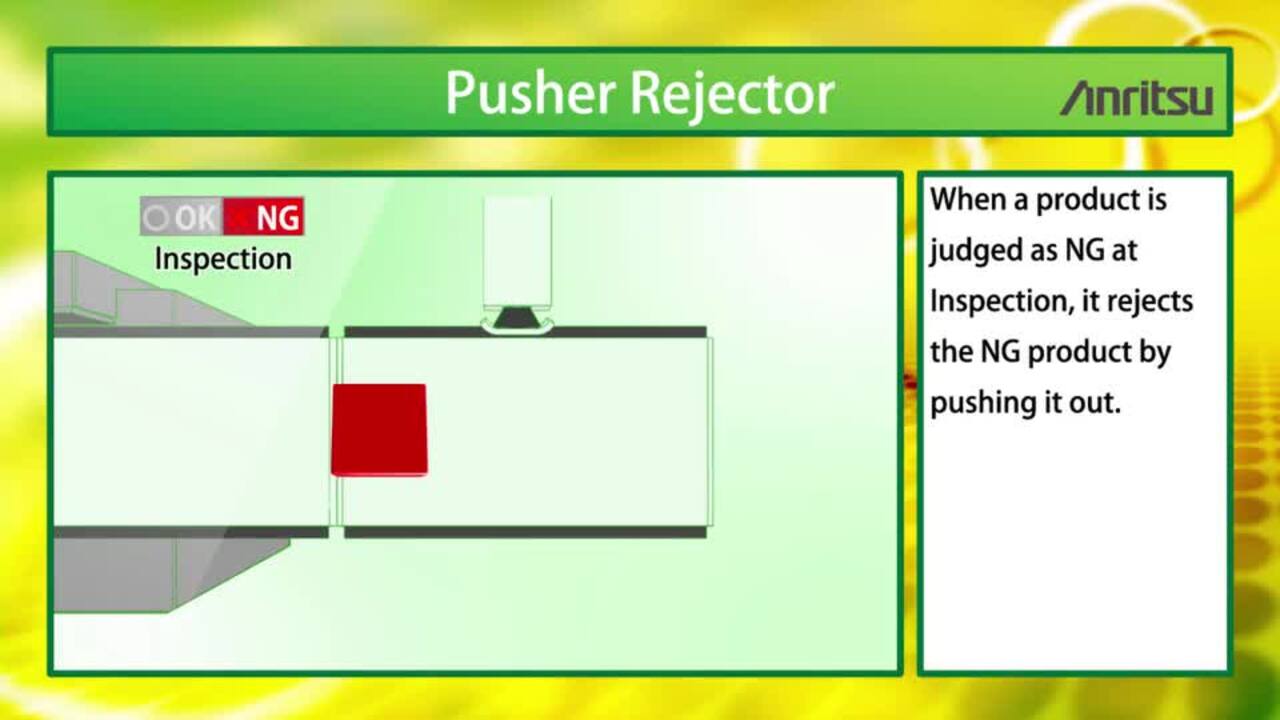

Pusher Rejector

Defective products are pushed off the line sideways by the action of a gate attached to an air cylinder. It is suitable for cartons.

0:31

-

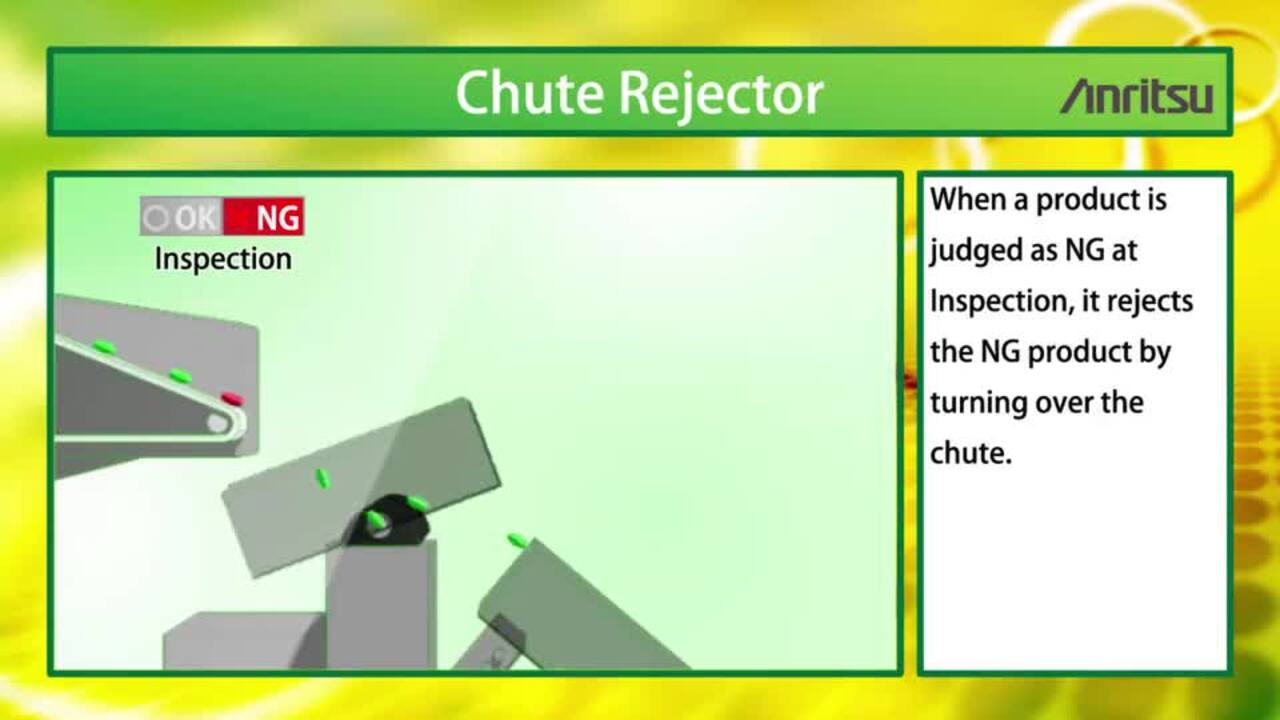

Chute Rejector

Reject defective products by turning over the chute. It is suitable for dry foods, frozen products, candies, etc. in bulk feeding.

0:31

-

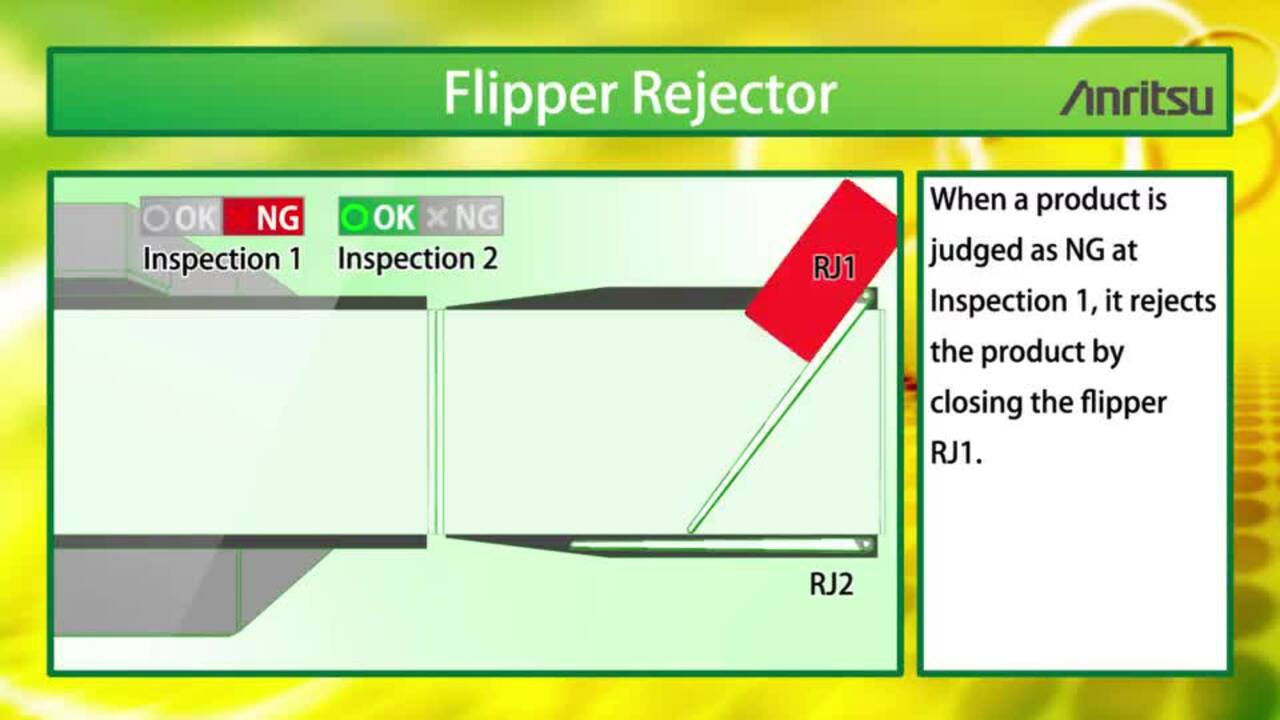

Flipper Rejector

Defective products are pushed aside by the rejector gates (flipper arms). It is ideal for products in boxes and thick bags.

0:56

-

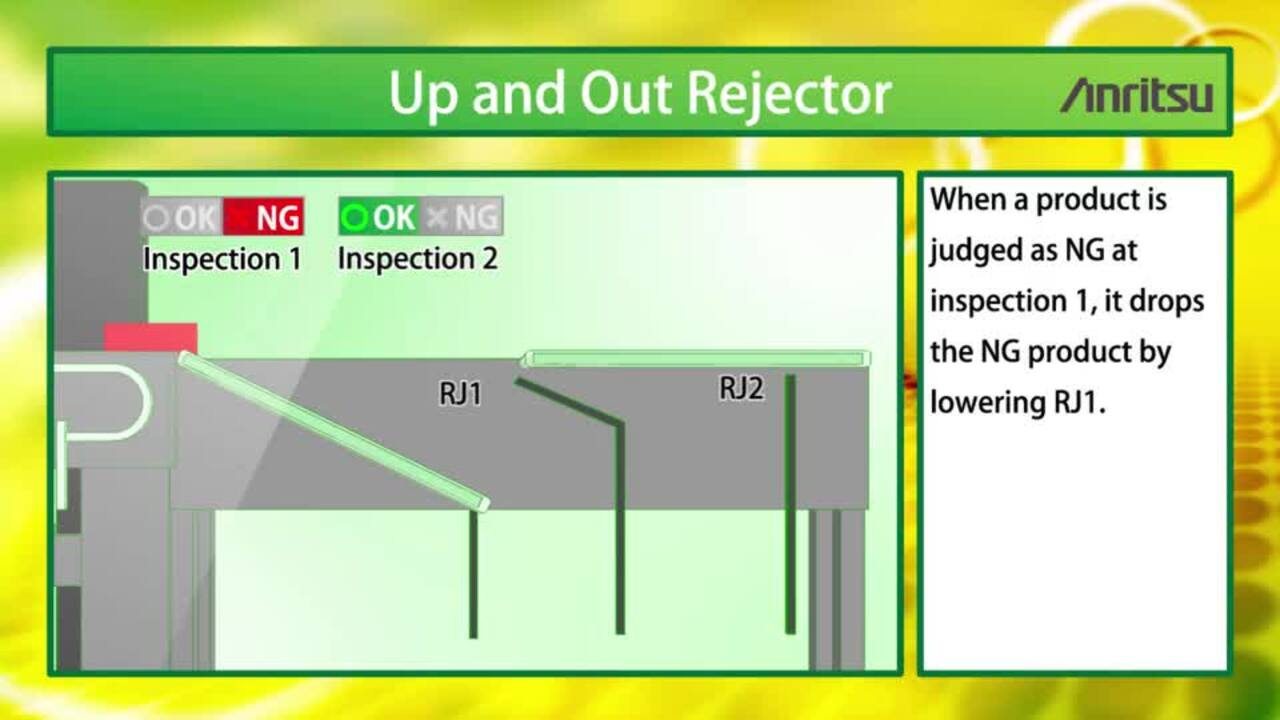

Up and Out Rejector

The rejection conveyor consists of two sections, one swings up and the other swings down so that the defective product drops out of the line in two classifications. It is suitable for products in thin bags.

0:48

-

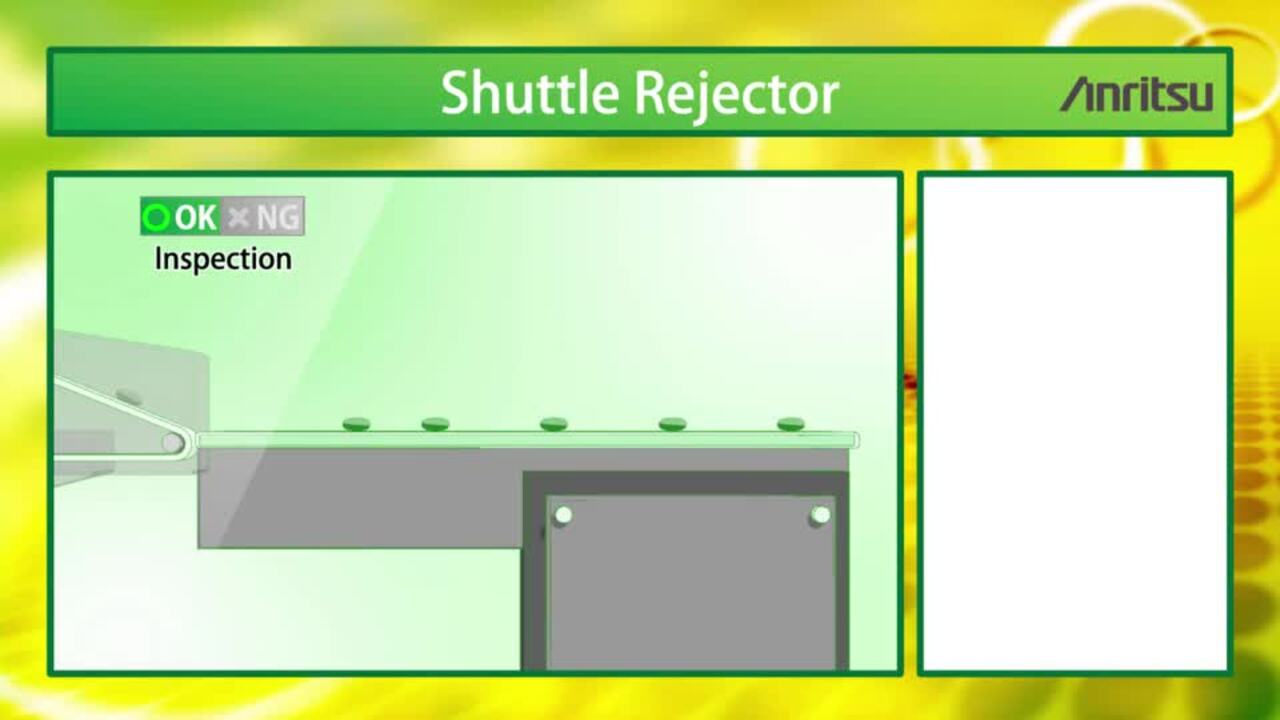

Shuttle Rejector

The belt on the rejector is expanded/contracted during the rejection to let the rejected products fall. It is ideal for unpackaged animal products and sticky bulk products.

0:31

-

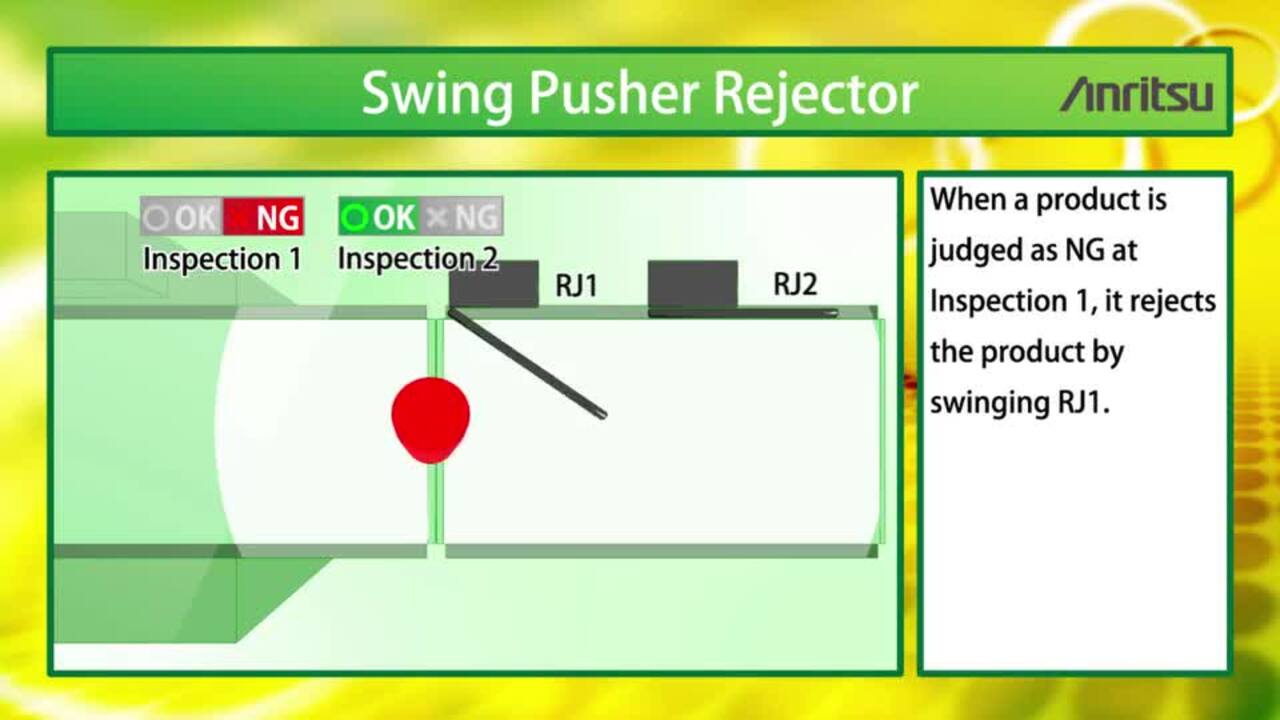

Swing Pusher Rejector

The tall arm swings to push defective products off the line. It is ideal for tall products in a standing position.

0:31

-

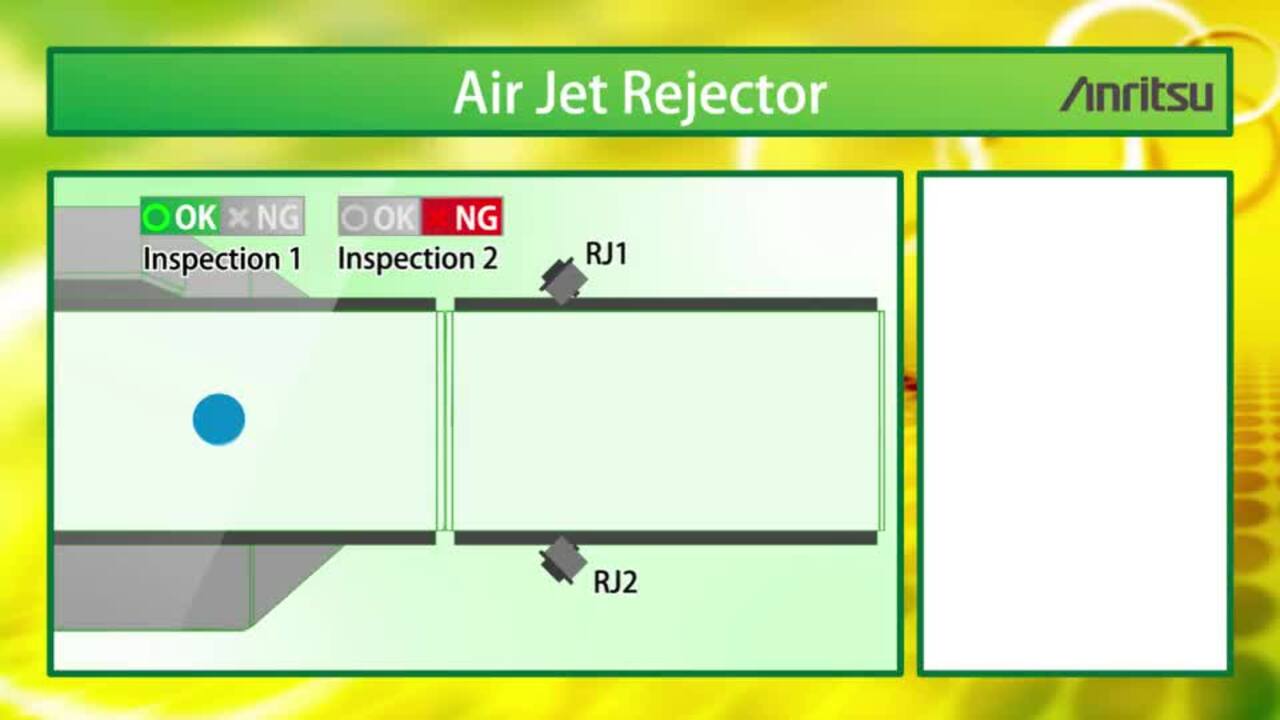

Air Jet Rejector

Defective products are blown sideways off of the line by a powerful air blast. It is ideal for small, lightweight packaged products.

0:42

-

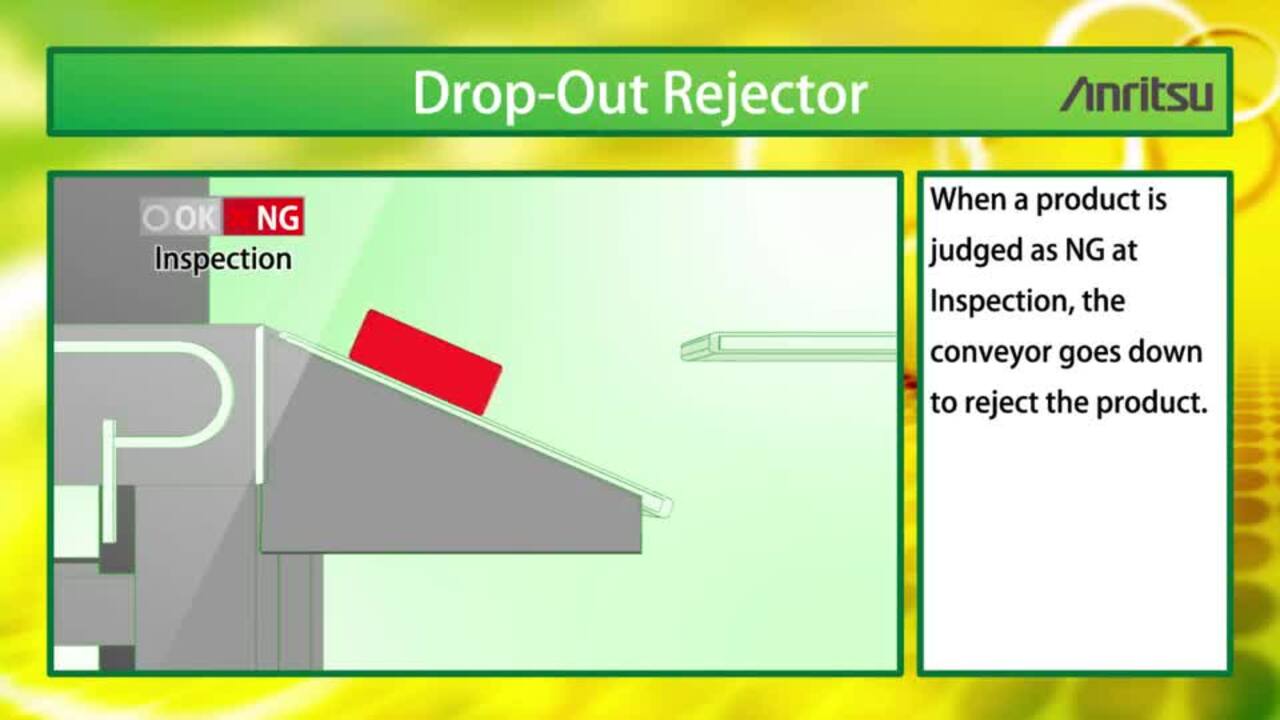

Dropout Rejector

The rejection conveyor swings down to drop the defective product. It is ideal for products in thin bags.

0:43